Understanding Crusher Run, Ballast, and Riprap

Introduction to Aggregate Materials

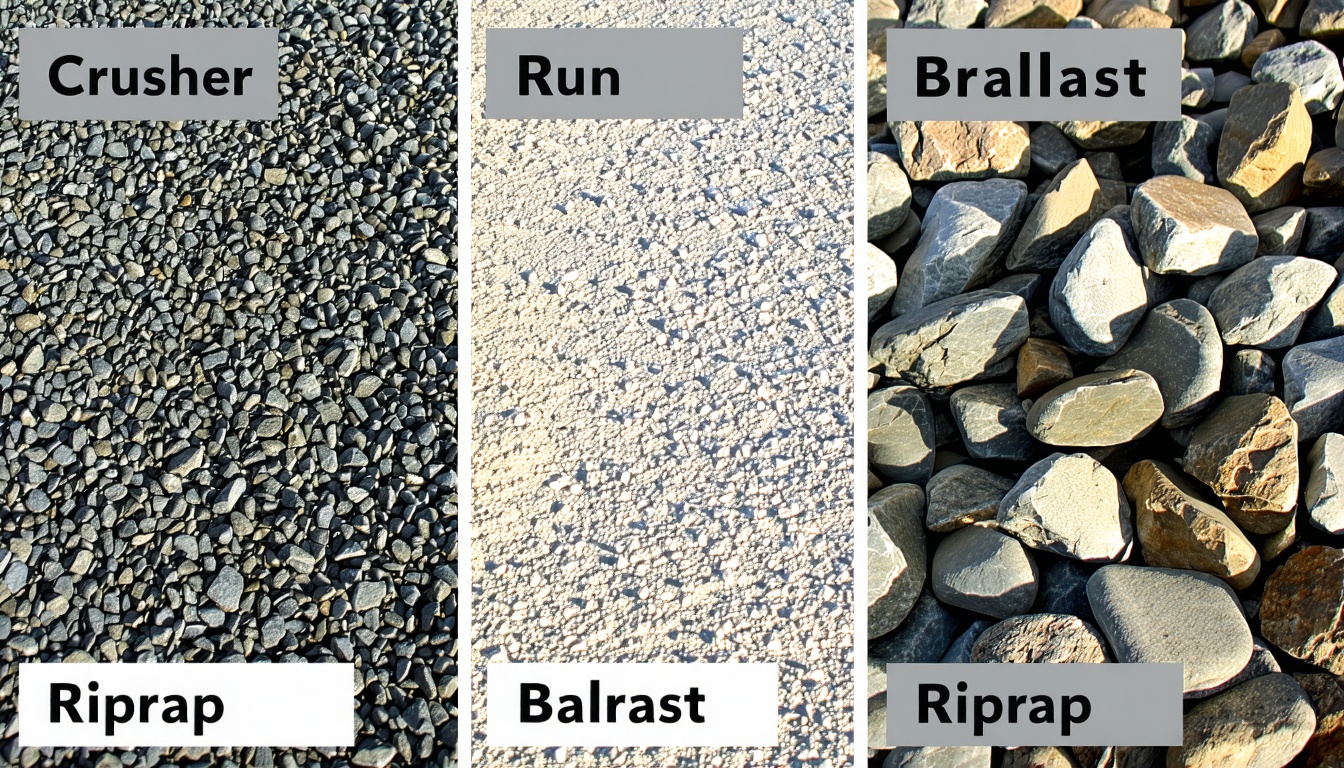

When exploring gravel and stone options, it is essential to understand the types and characteristics of aggregate materials. Three popular choices are crusher run, ballast, and riprap. Each has unique properties that make them suited for various applications, and knowing the differences can help in making the right choice for your project.

Characteristics and Uses of Crusher Run

Crusher run is a blended mix of coarse and fine aggregate, valued for its low void content, which enhances compaction and drainage capabilities. The typical sizes range from 1/2″ to 4″, making it ideal for use under concrete slabs, patios, driveways, sidewalks, and walkways. The versatility offers us a reliable foundation for constructing stable surfaces.

| Size of Crusher Run | Common Uses |

|---|---|

| 1/2″ | Driveways, Walkways |

| 3/4″ | Patios, Sidewalks |

| 3″ to 4″ | Sub-bases, Heavy construction |

To properly install crusher run, it is necessary to prepare the subgrade, then spread the material using a bobcat or skid steer before compaction. This process is crucial for creating a firm sub-base, ensuring that the subsequent layers perform optimally (TriStar Concrete).

Applications of Ballast vs Riprap

While both ballast and riprap are aggregate materials, they serve different purposes. Ballast is primarily used in railroad construction, providing stability for track alignment and maintaining the position of the rails. Its angular shape allows for interlocking, which prevents shifting that could disrupt train operations.

On the other hand, riprap is used for erosion control, often placed along shorelines or riverbanks to protect against wave action and water flow. The large, loose stones absorb the energy of the water, preventing soil erosion and creating a stable environment.

| Aggregate Material | Primary Use |

|---|---|

| Ballast | Railroad tracks stabilization |

| Riprap | Erosion control in waterways |

Understanding these differences can assist us in making informed decisions about which aggregate material best suits our specific project needs. For further insight into choosing suitable materials, explore our resources on choosing the right gravel type for your landscaping project and the benefits of using recycled concrete in driveways and paths.

Deciding on the Right Aggregate Material

Choosing the right aggregate material can be complex. We must consider various factors that influence our decision, as well as practical aspects for different projects. The long-term benefits and cost-effectiveness of each material are equally important to evaluate.

Factors Influencing Material Choice

When selecting between crusher run, ballast, and riprap, we need to consider several influencing factors. These include the specific application, environmental conditions, and project requirements.

| Aggregate Type | Ideal Use Cases | Environmental Suitability |

|---|---|---|

| Crusher Run | Driveways, pathways, and base layers | Well-suited for stable, compacted applications |

| Ballast | Railroad tracks, foundations | Ideal for areas requiring weight support and drainage |

| Riprap | Erosion control on slopes, shorelines | Effective in regions with concentrated runoff and high velocities |

Practical Considerations for Various Projects

Each type of aggregate serves a distinct purpose in construction and landscaping. Understanding the characteristics of these materials helps us make informed decisions.

- Crusher Run is best used for creating a solid base under driveways or foundations. Its blend of stone and dust binds together, creating a compact, sturdy layer.

- Ballast is specifically designed for railway applications, providing stability and drainage for tracks. It minimizes movement and supports the weight of trains effectively.

- Riprap is utilized for stabilizing slopes and preventing erosion. It is particularly effective in areas where vegetation growth cannot occur due to environmental conditions, making it desirable for shorelines and riverbanks (Minnesota Pollution Control Agency).

Cost-Effectiveness and Long-Term Benefits

While initial costs can vary, understanding long-term benefits is essential for our investment.

- Riprap, though its initial installation costs range from $30 to $65 per square yard, offers minimal maintenance and extended service life, making it cost-effective over time (Insta-Turf). Its versatility allows it to be used in multiple settings, providing erosion control while supporting aquatic habitats and water quality (Hello Gravel).

- Crusher Run is consider highly cost-effective for foundational projects due to its compact stability.

- Ballast generally provides excellent long-term stability, minimizing the need for frequent repairs.

We encourage everyone to assess their specific project needs and consider factors such as application, environmental conditions, and the long-term benefits of materials. For further assistance, feel free to explore our guide on choosing the right gravel type for your landscaping project.

Exploring Crusher Run for Construction

Crusher run is a versatile aggregate material that plays a critical role in many construction projects. By understanding the quarry process, advantages, and installation best practices, we can maximize its potential for our needs.

Quarry Process Details

Crusher run is produced through a meticulous process where larger rocks are crushed into smaller pieces, creating a blend of coarse aggregate and fine aggregate. This unique composition offers low void content, making it invaluable for concrete construction due to its excellent compaction capability and drainage characteristics. It typically ranges in sizes from 1/2″ to 4″ and is most commonly used beneath concrete slabs, patios, driveways, sidewalks, and walkways (TriStar Concrete).

When ordering crusher run, it’s important to note that it is sold by the ton and weighs roughly 2,500 pounds per cubic yard. Proper volume calculations are necessary to ensure that we purchase the correct amount for our projects. Delivery options are often available through the quarry, which uses dump trucks, or we can arrange for pickup using a dump truck or dump trailer for transportation (TriStar Concrete).

Benefits of Using Crusher Run

Crusher run provides numerous advantages for construction projects, which include:

| Benefit | Description |

|---|---|

| Durability | The blend of coarse and fine aggregates offers strength that withstands various weather conditions. |

| Drainage | Its low void content encourages effective water drainage, reducing water pooling and erosion. |

| Ease of Use | The material is easy to work with, making it suitable for both professional contractors and DIY enthusiasts. |

| Cost-Effectiveness | Crusher run is generally more affordable than other aggregate options, maintaining quality and performance. |

Using crusher run can enhance the structural integrity of a project while remaining budget-friendly.

Best Practices for Installation

Installing crusher run requires specific best practices to ensure effective compaction and durability. Here are the steps we recommend:

- Prepare the Subgrade: Ensure the area is level, free of debris, and compacted to create a solid foundation.

- Spread the Material: Use a bobcat or skid-steer to evenly distribute the crusher run over the prepared area. This helps achieve a uniform layer.

- Compact the Crusher Run: Properly compact the material using a plate compactor or roller to solidify the base. This step is crucial for preventing settling and providing a stable surface.

- Check for Levelness: After compaction, check the surface level to ensure proper drainage and alignment with construction plans (TriStar Concrete).

- Optional Layering: Depending on the project, multiple layers of crusher run can be placed and compacted for increased thickness.

For more insights on using aggregates in different projects, consider exploring topics such as installing a gravel driveway: step-by-step material guide or how to create a functional french drain with aggregate rock. These resources can provide further guidance on effective aggregate application and installation.

Utilizing Ballast for Stabilization

Ballast plays a crucial role in the stability and functionality of railroad tracks. Understanding its importance helps us in selecting the right materials for our projects.

Role of Ballast in Railroad Tracks

Ballast acts as a support system for railway tracks, providing stability and preventing movement. Typically, railroad ballast utilizes riprap stones that range from 3 to 4 inches in diameter, offering the necessary support to hold the tracks in place while allowing for drainage (Al Blair Construction). This material is essential in maintaining the alignment and integrity of railway lines, ensuring safe transportation.

Performance and Stability of Ballast

The performance of ballast is determined by its ability to distribute loads and minimize shifting under pressure. When properly installed, ballast provides excellent stability against shifting caused by trains passing over the tracks. It also helps to manage water drainage effectively, reducing the risk of erosion and track displacement. Key factors influencing ballast performance include the material’s size, shape, and the compaction process used during installation.

| Ballast Type | Size Range | Key Benefit |

|---|---|---|

| Standard Ballast | 3 – 4 inches | Excellent stability and drainage |

| Crushed Stone Ballast | Varies | Adaptable for various conditions |

| Recycled Concrete Ballast | Varies | Environmentally sustainable option |

Choosing the right type of ballast is essential for long-term performance and maintenance costs.

Choosing the Right Ballast Size

Selecting the appropriate ballast size is critical for the effectiveness of the stabilization. For railroad applications, larger stones (3 to 4 inches) are preferred to ensure load distribution and prevent movement. Additionally, the choice of ballast size should consider the specific environmental conditions it will be subjected to, such as water flow and soil type.

For more information on materials suitable for landscaping projects, check out our guide on choosing the right gravel type for your landscaping project. Comparing different aggregate materials can help ensure efficacy and durability in our construction efforts.

Ultimately, understanding the properties and applications of ballast allows us to make informed decisions that will lead to successful and sustainable infrastructure in our projects.

Protecting Against Erosion with Riprap

Riprap for Erosion Control

Riprap is a popular aggregate material utilized for erosion control in various environments. It is particularly effective for stabilizing slopes, channels, streambanks, shorelines, and areas prone to concentrated runoff. Its use is especially advantageous in locations where conditions make vegetation growth difficult because of high velocities and challenging soil conditions (Minnesota Pollution Control Agency).

The classification of riprap can vary depending on the installation method and stone size. According to the Minnesota Department of Transportation, riprap can be categorized as random riprap or hand-placed riprap. This versatility allows for customized solutions based on specific site requirements.

Benefits and Effectiveness of Riprap

The benefits of employing riprap for erosion control are numerous:

-

Effectiveness: Studies indicate that properly installed riprap can reduce flow velocity by up to 60% compared to bare soil surfaces. Additionally, it can decrease soil erosion rates by over 90% when compared to unprotected slopes.

-

Longevity: Once installed, riprap can provide continuous erosion protection for decades, requiring minimal maintenance or replacement.

-

Surface Roughness: By increasing surface roughness, riprap significantly slows down runoff, preventing the erosion of critical areas.

Here’s a comparative look at riprap’s installed costs versus other erosion control methods:

| Erosion Control Method | Average Installed Cost per Square Yard |

|---|---|

| Riprap | $30 – $65 |

| TRMs (Turf Reinforcement Mats) | $6 – $22 |

Although riprap may have higher initial costs due to equipment and handling, its durability and long-term benefits offer a compelling value proposition for erosion control projects (Insta-Turf).

Installation and Maintenance Guidelines

Riprap is relatively simple to install compared to other erosion control practices. Basic installation steps include:

- Site Preparation: Clear and level the area where riprap will be installed.

- Placement: Lay the riprap stones in a configuration that ensures adequate coverage and stability.

- Compaction: Compact the stones to enhance stability, ensuring they are secure.

While maintenance is minimal, regular inspections are necessary to ensure the riprap remains intact and effective. Over time, stones may shift or become dislodged due to weather or water flow, necessitating occasional adjustments to maintain functionality.

In summary, riprap stands out as a highly effective solution for controlling erosion in various landscapes. It provides solid long-term protection and, with our guidance at McGirt Supply Yard, we can help ensure you have the right materials for your project. For further insights, don’t forget to check out our guide on choosing the right gravel type for your landscaping project.

Comparing Aggregate Base Materials

When considering which aggregate materials to use, understanding the various types available is crucial for making an informed decision. This section will cover the types of aggregate bases, important soil and climate considerations, and best practices for installation and maintenance.

Types of Aggregate Bases

Different types of aggregate bases serve various purposes in construction and landscaping. Common materials include gravel, crushed stone, sand, and recycled products like crushed concrete and asphalt. Each type possesses unique characteristics suited for specific applications.

| Aggregate Type | Characteristics | Common Uses |

|---|---|---|

| Gravel | Durable, drains well, and easy to work with. | Driveways, foundations, erosion control. |

| Crushed Stone | Provides strong support and stability. | Base for roads and structures. |

| Sand | Good drainage, lightweight, and affordable. | Filler material, landscaping, and volleyball courts. |

| Recycled Materials | Sustainable option, cost-effective. | Driveways, paths, environmental projects. |

It’s crucial to select the right material for your project’s requirements. For example, gravel is often recommended for landscape projects owing to its outstanding drainage capabilities, while crushed stone excels in load-bearing applications.

Soil and Climate Considerations

The type of soil and climate in which you are working impacts the choice of aggregate base. Factors such as drainage requirements, precipitation levels, and soil composition must be taken into account:

- Clay Soils: Require more permeable materials like gravel or crushed stone for proper drainage.

- High Rainfall Areas: Necessitate durable materials to resist erosion and withstand heavy moisture.

- Extreme Weather Conditions: May demand robust aggregates that can endure environmental stresses.

For additional insights on choosing the correct gravel type for specific projects, refer to our guide on choosing the right gravel type for your landscaping project.

Installation and Maintenance Tips

Proper installation and maintenance are integral for the longevity and effectiveness of aggregate bases. Here are best practices to enhance your project results:

- Site Preparation: Clear the work area of debris, vegetation, and organic materials.

- Proper Grading: Ensure the surface is graded appropriately to promote effective drainage.

- Compaction Techniques: Use compactors to create a solid base that minimizes settling over time.

- Regular Maintenance: Monitor the installation and perform repairs as needed to prevent erosion and structural issues.

Following these recommendations will ensure a successful installation that meets your project goals. For more insights on aggregate materials applied to various projects, consider our articles on how to use aggregate #57 for drainage and erosion control and installing a gravel driveway: step-by-step material guide.

By taking into account the types of aggregate bases, soil conditions, and effective installation strategies, we can ensure that our projects utilize the best materials for lasting stability and durability in any environment.